Built upon years of extensive professional experience, these products are meticulously designed and manufactured to meet users' exact requirements. Through continuous innovation, technological advancement, and ongoing optimization, this model has emerged as the industry-leading portable, mobile, and stationary equipment for valve maintenance and inspection.

Key features:

1. The complete set of equipment— including the grinder main unit, grinding head housing, grinding disc, clamping mechanism, and more—is all stored in a vehicle-mounted case for convenient mobility.

2. The main component features a quick-assembly short-pitch square-threaded structure, making assembly and disassembly convenient and efficient.

3. The clamping and pressurizing mechanism allows the grinding head assembly to be easily adjusted in three dimensions—up/down, left/right, and forward/backward. Additionally, the output of the grinding head assembly features a ball-head floating design, ensuring optimal contact between the grinding disc and the workpiece’s sealing surface, thereby guaranteeing precise grinding results.

4. Equipped with an ultra-thin grinding head and grinding disc, suitable for particularly narrow valve seats.

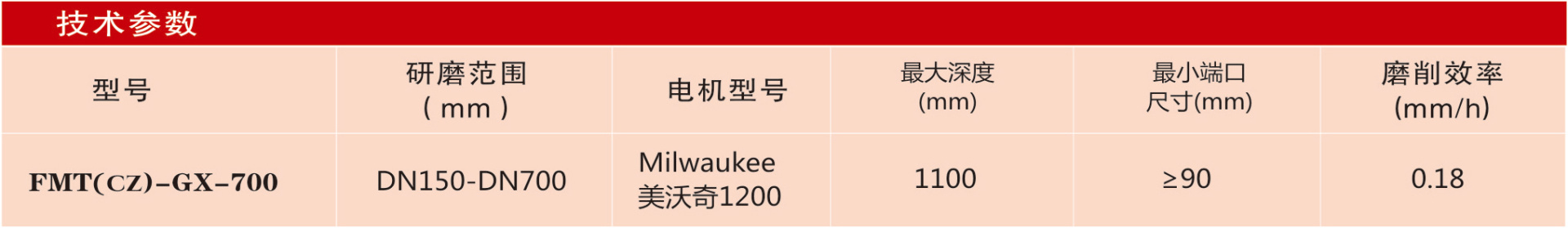

5. The ultra-thin grinding discs feature a free-assembly design, allowing for adjustments within the specified range. Six discs can simultaneously machine the sealing surfaces of valve bodies and valve flaps, covering a processing range from φ150 to φ700.

6. The workbench is equipped with an electrically adjustable fixture for angle adjustment (0–15°) and an electric spring-loaded pressure device (which allows precise, repeatable application of the set pressure onto the sealing surface), ensuring effortless, rapid, and high-quality grinding of the valve disc.

7. For rough grinding, high-quality diamond tools are used to eliminate defects on the grinding surface—followed by precision finishing with shaped sandpaper (back-adhesive sandpaper is not employed). This method is easy to use, significantly boosting both efficiency and product quality. Grinding accuracy achieves radial fitting better than 80%, with a surface roughness of just 0.2 μm.

8. The machine can be equipped with an illumination system, and a dedicated inspection tool allows for visual inspection of deep-hole sealing surfaces.