The J1QP-GX series of pipe cutting and beveling machines enables on-site cutting and beveling of endless pipes. This machine features a compact design and superior performance, offering versatile beveling options along with safe and easy operation. It is particularly well-suited for on-site processing of thick-walled pipes subjected to high temperatures, high pressures, and ultra-high pressures in industries such as petroleum, chemical engineering, thermal power, nuclear power, and boiler manufacturing.

Available in three power types—electric, hydraulic, and pneumatic—and categorized into three functional models—standard, reinforced, and specialized—users can select the model that best fits their specific site conditions.

Key features include:

1. Complete pipe cutting and beveling operations in a single clamping process.

2. Capable of performing online machining on endless pipes directly at the job site.

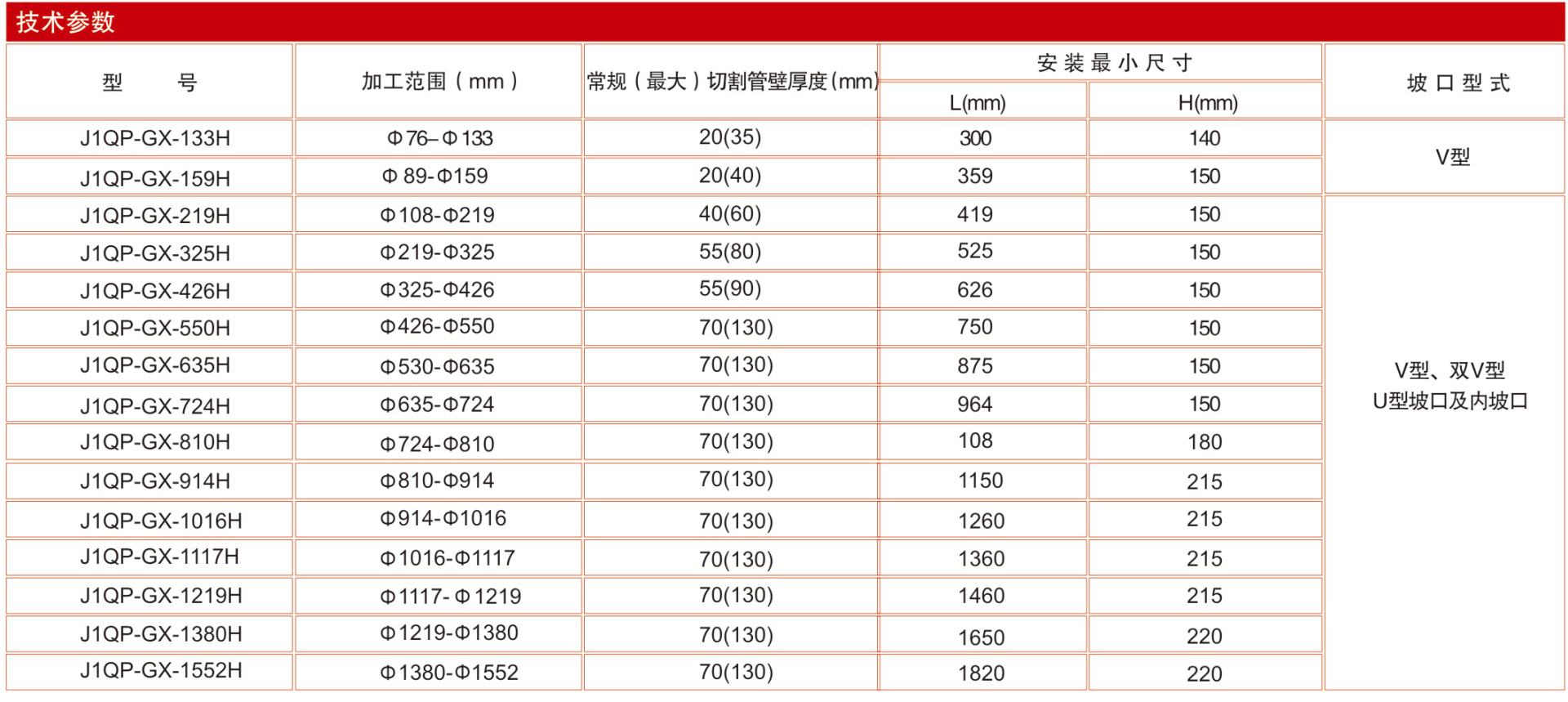

The J1QP-GX series of pipe cutting and beveling machines enables on-site cutting and beveling of seamless pipes. Featuring a compact design and outstanding performance, these machines offer versatile beveling options while ensuring safe and easy operation. They are particularly well-suited for on-site processing of high-temperature, high-pressure, and ultra-high-pressure thick-walled pipelines in industries such as petroleum, chemical engineering, thermal power, nuclear power, and boiler manufacturing. The machines are available in three power types—electric, hydraulic, and pneumatic—and can be categorized into three functional models: standard, reinforced, and specialized, allowing users to select the most appropriate model based on their specific site conditions.

Key features:

1. One-time clamping is all it takes to complete pipe cutting and beveling operations.

2. Online processing of seamless pipes is available.

3. The processing pipe diameter range is wide: the standard model accommodates variations of around 130 mm, while the reinforced model can handle variations of approximately 180 mm.

4. The system can process tubes with significant wall thicknesses—up to 90 mm for the standard model and up to 130 mm for the reinforced version.

5. Powered by robust performance: Models below 325 are equipped with a genuine 1300W Maibao motor made in Germany, while models above 325 feature a high-power, imported 2300W motor.

6. High-performance rolling elements significantly extend the machine's lifespan.

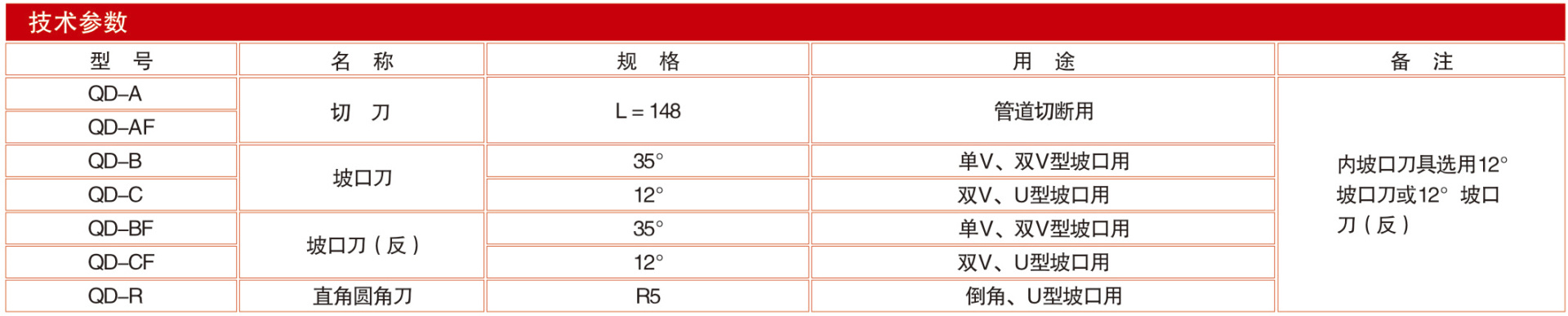

J1QP-GX Series Pipeline Cutting Beveling Machine Dedicated Tools

J1QP-GX Series Pipeline Cutting Beveling Machine Dedicated Tool Parameters