The J1P-GXZ series of external clamp-type automatic beveling machines are specialized tools designed for pre-weld bevel preparation on pressurized pipelines. Developed in accordance with international standards for medium- and high-pressure pipeline maintenance, this model also takes into account the specific conditions of domestic 300,000 kW to 1 million kW power generation unit piping systems and valves. It was specifically engineered to address the unique challenges of narrow working spaces and large-scale maintenance volumes commonly encountered in industries like thermal power generation. As a result, it has become the industry’s mainstream product and has maintained its leading position for ten consecutive years.

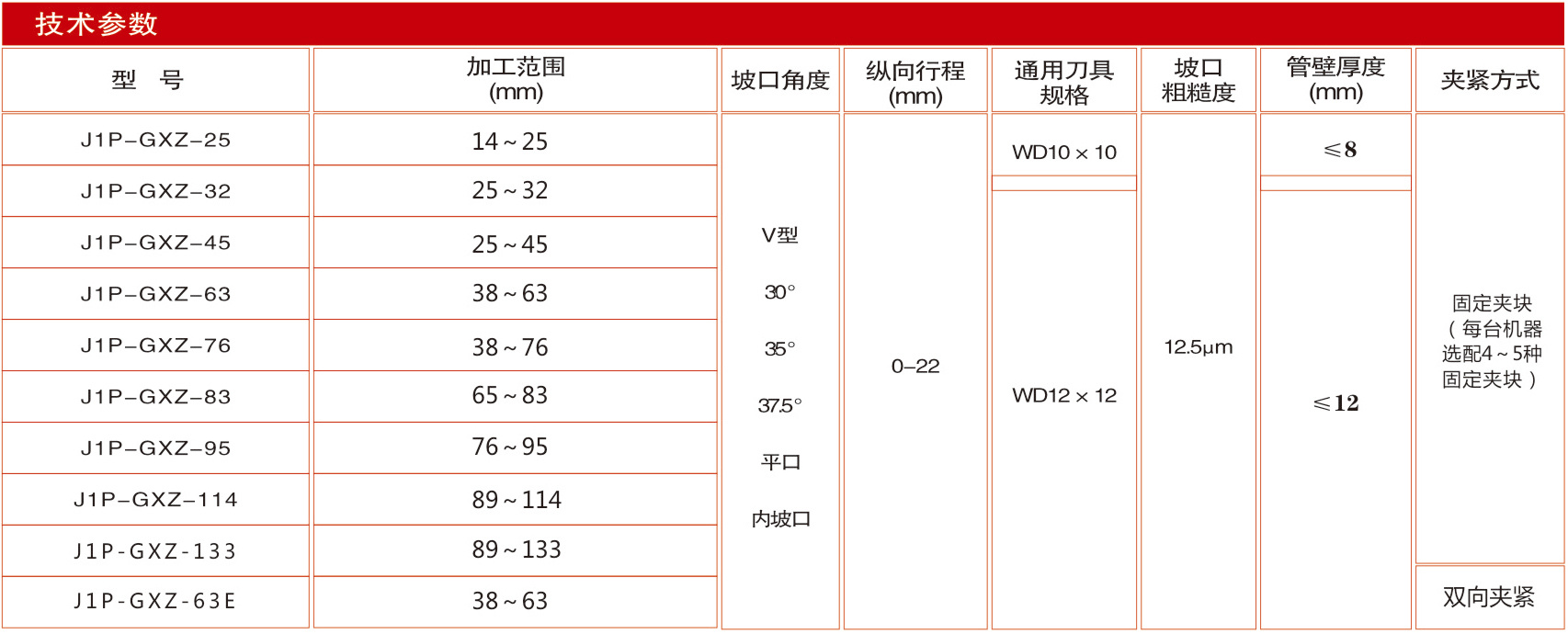

The J1P-GXZ series automatic beveling machines are available in three models: universal, compatible, and special.

Key features:

1. The equipment’s external dimensions, specifically designed for dedicated components such as water-cooled walls, superheaters, reheaters, and economizers, are optimized to meet the demands of various complex on-site conditions.

2. A clever automatic tool-in and tool-out mechanism maximizes weight reduction of the entire machine, simplifies operation, boosts efficiency, and significantly lowers labor intensity. The精选ed carbide cutting tips are designed to handle the machining of various grades of alloy steel pipes with ease.

3. Precision-engineered carbide cutting tips that can handle the machining of various alloy steel pipes.

4. Equipped with a custom-made "metaboGXT" special motor, exclusively designed for "Kaohsiung Tools" and generously supported by Germany's leading company, Metabo. This motor features the brand’s original Marathon rotor and an ultra-durable gear set, delivering significantly greater power and exceptional endurance—qualities that set it apart from standard Metabo drill motors.

5. Multiple positioning and clamping methods—compact, lightweight, with precise centering and stable, reliable clamping for convenient use.

6. Optional dedicated tools allow for machining internal threaded pipes.

7. Optional pneumatic motors available to meet diverse on-site requirements.

8. The processing scope can be appropriately expanded based on user requirements. (Note: Add "H" after the extended type.)